The coatings of anilox rollers with ceramic have always guaranteed robust and wear-resistant surfaces. The modern ceramic layers of TLS Anilox are resistant to wear, moisture and heat. Special barrier layers between the base material and the ceramic prevent the penetration of paint and aggressive cleaning agents and thus the corrosion of the roller body.

The reproducibility of your print results is thus guaranteed for a long period of time.

Durable anilox rollers thanks to high-quality ceramic coatings

The ceramic coating embodies the high-quality basis of the anilox roller.

For high-precision laser engraving, the ceramic coating must be absolutely homogeneous. We guarantee you unique purity and hardness, because TLS Anilox only uses high-quality ceramic powder in the most modern coating systems.

The ceramic coating newly developed in Salzkotten gives your anilox rollers and sleeves both lasting resistance and a long service life.

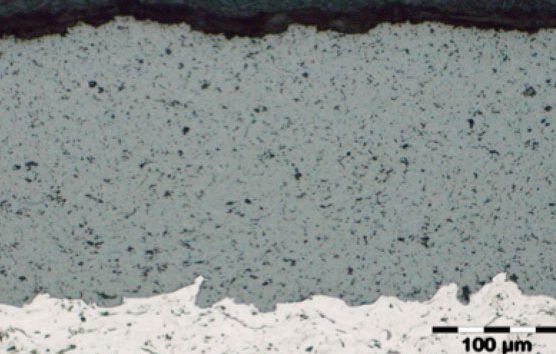

Layer image of the Cr2O3 ceramic coating

At the same time, we offer a portfolio of laser engravings that can be used in various application areas such as flexible packaging, labels & labels, as well as the coating area.

We offer a wide variety of laser engravings. Various engraving profiles have been and are being developed to meet even the most demanding requirements of a homogeneous surface. With the help of a wide variety of engraving geometries, the respective order volume and lying behavior can be optimized.

You would like to optimize your order image, contact us, we will be happy to advise you and find it

always the customer-oriented solution.

Tero Lux

The ceramic coating of anilox rollers has proven itself for three decades now. Nevertheless, the research and development department of TLS Anilox GmbH is exploring further potential for optimization.

In this development process, we were able to overcome the residual porosity of the ceramic layer and advance into the limitless area of the finest lines. Discover with us TeroLux™, our (r)evolutionary carbide coating.

A newly developed laser with a unique laser source enables the innovative TeroLux™ patented metal coating to be engraved.